Electric motors are an essential component of modern industrial systems, powering a vast array of machinery and equipment in industries ranging from maritime engineering to manufacturing. Whether it's an AC or DC motor, keeping it operating at peak efficiency is essential to guarantee smooth operations. Motors experience wear and tear over time, which can result in unexpected malfunctions, increased energy consumption, and lower efficiency. Maintaining your equipment's dependability, efficiency, and affordability with routine motor overhauls and maintenance is one of the best strategies to fight these problems.

Ghaima Group, a reputable electro mechanical company, specializes in rewinding and overhauling AC and DC motors since we recognize the value of these components and help businesses in Dubai and around the UAE preserve operational efficiency. In this article, we'll look at the benefits of professional maintenance, the reasons why routine motor overhauls are essential for industrial operations, and how to recognize the symptoms that a motor requires repair.

Many industrial systems are built around motors, which supply the energy needed to keep machinery operating. But with time, motors are prone to deterioration just like any other mechanical equipment. Motors working continuously without sufficient maintenance can result in greater operating costs, decreased efficiency, and even catastrophic failures. The following are some main justifications for why routine overhauls are necessary to preserve motor longevity and performance:

Avoiding Downtime: Unexpected motor failure is less common in well-maintained motors. Frequent overhauls can assist in identifying possible problems early on and taking action before they become serious issues that result in expensive downtime. Even a brief period of downtime can cause large financial losses for firms that primarily depend on continuous output.

Enhanced Energy Efficiency: When motors age, they frequently need more energy to carry out the same job. Operating costs go up as a result of this increasing energy use. Periodic maintenance guarantees that motors are operating at peak efficiency, minimizing energy loss and cutting power costs.

Increased Motor Lifespan: A motor's lifespan can be considerably increased with routine maintenance. Overhauls save organizations money by extending the operational life of motors and preventing long-term damage, such as electrical imbalances, worn-out bearings, and insulation breakdown.

Assures Safety: In businesses with large machinery, malfunctioning motors can provide significant safety hazards. Accidents or equipment damage may arise from mechanical breakdowns, electrical problems, or overheating. Frequent overhauls guarantee that motors are running within safe bounds, safeguarding both personnel and machinery.

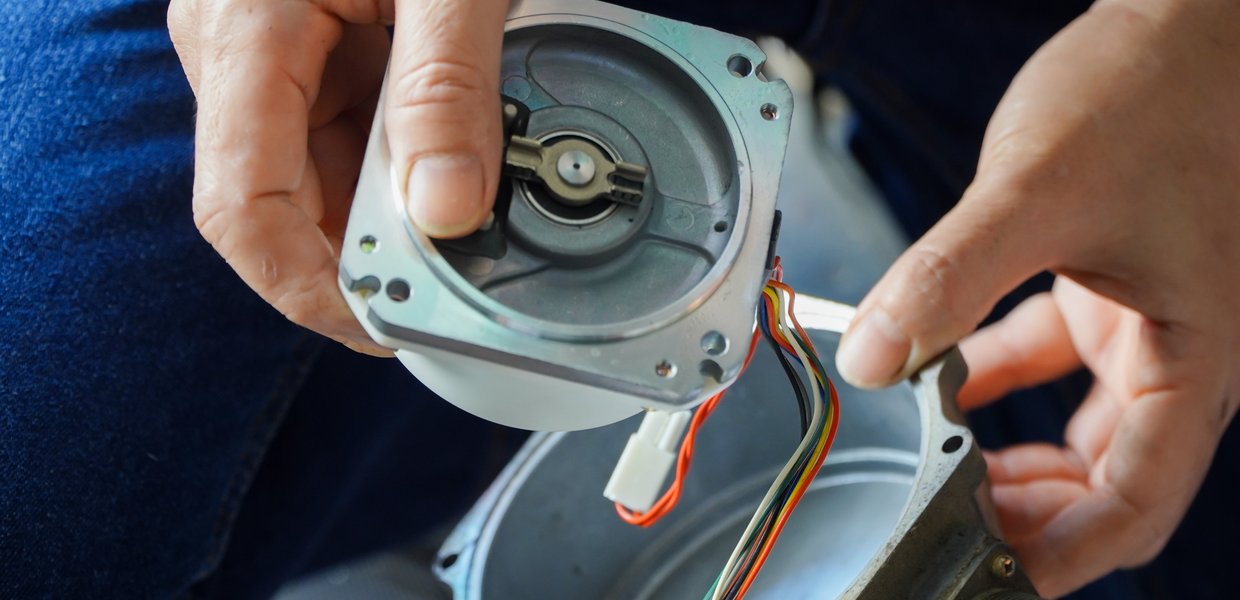

At Ghaima Group, we bring years of experience in providing electromechanical solutions, specializing in motor rewinding and overhauling services for AC and DC motors. Our team of experts is equipped with the latest diagnostic tools and technology to assess and repair motors, ensuring they operate at peak performance. Whether it’s a small DC motor or a high-tension (HT) AC motor, our comprehensive overhaul process is designed to minimize downtime and enhance motor longevity.

Knowing when to schedule a motor overhaul is key to preventing costly breakdowns and ensuring uninterrupted production. Here are some common signs that your motor may need attention:

Unusual noises such as grinding, squealing, or clicking could indicate worn bearings, misalignment, or loose components, all of which should be addressed immediately.

Motors that are running hotter than normal may be experiencing insulation breakdown, inadequate ventilation, or excessive friction, all of which can lead to serious damage if not resolved.

Increased vibration is often a sign of mechanical imbalance or misalignment. This can lead to accelerated wear on components and ultimately cause motor failure if not addressed.

If your motor is struggling to maintain its usual performance levels or is consuming more energy than normal, it may be time for an overhaul.

Frequent tripping of circuit breakers or fuses can indicate electrical problems within the motor, such as short circuits or winding issues, which require professional attention.

Regular motor overhauls offer numerous benefits to businesses, particularly those that rely on the continuous operation of critical machinery. By partnering with a trusted provider like Ghaima Group, businesses can expect:

Improved energy efficiency and fewer breakdowns translate to lower operational costs and higher profitability.

Scheduled maintenance and overhauls prevent unexpected failures that could disrupt production schedules.

Motors run at maximum efficiency with routine maintenance, giving dependable power to necessary machinery and lowering the possibility of unplanned breakdowns.

Well-maintained motors reduce the likelihood of dangerous malfunctions, contributing to a safer working environment.

In industries where equipment reliability is paramount, regular motor overhauls are essential for maintaining optimal performance and minimizing downtime. Ghaima Group’s expertise ensures that businesses across Dubai and the UAE can keep their operations running smoothly. By investing in regular maintenance, companies can enhance motor efficiency, extend equipment life, and reduce operational costs, making motor overhauls an indispensable part of industrial operations.