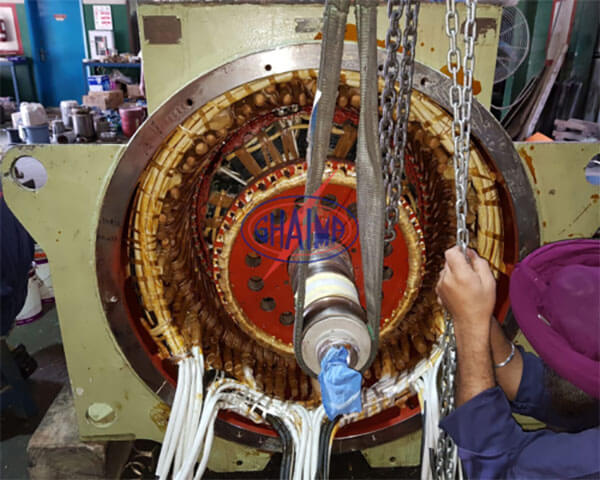

Ghaima Group has long been a leader in precise, highly accurate services like vibration analysis, inspection, laser alignment, and repair. We have a solid reputation as a highly dependable contractor for mechanical services like thermographic inspection, servo motor repair, valves, induction motor repair, pumps, and other rotational and electric equipment, on-site machining & bolting, in-shop machining, heat treatment, piping, and other general mechanical services to support you in your daily operations. Our knowledgeable professionals can handle any DC and AC motor repair and rewinding. The equipment, procedures, and technology we employ are all continually being updated.

No matter how easy or difficult the repair is, our facility is fully equipped to handle it, including servo motor repair, induction motor repair, gearbox overhaul, and overhaul electric motor. We have you covered with the machine work on end bells or motor shafts, basic bearing replacements, to install RTD, vibration analysis, full rebuilds, laser alignment, and thermographic inspection. We can spray shafts with nickel and chrome to restore them to their original specifications. To ensure that every project is finished to the greatest quality of excellence, our skilled machinists provide excellent mechanical services and work to the highest accuracy requirements.

Comprehensive testing to identify whether there is abnormal vibration by analyzing the levels and patterns of the vibration signals coming from the machinery or structure. It aids in general testing of the equipment or object's condition.

Two connected shafts are completely measured using a laser alignment instrument. This will show whether the shafts are straight and within a predetermined tolerance. The sensors are mounted on the shafts, and a laser beam is then fired to do this.

The functioning of moving parts in an industrial machine is balanced using dynamic balancing—this aid in determining the imbalance within the rotating component properly.

We perform a thermographic measurement of the parts using infrared video and still cameras. To do this, we image the temperature variation, fields, gradients, or patterns at the surface.

The resistance temperature detector is a sensor used to manage and check stability, precision, and repeatability as well as temperature. The resistance also increases as the temperature rises.

A Great Offer For An Excellent Decision

Our uncompromising focus on precision, accuracy and work ethics, together with our responsive customer service and innovative solutions, are the reasons why Ghaima Group is the engineering company of choice for ambitious clients who want to see their goals achieved at the highest level. Join them now!