Ghaima Group offers professional services for rewinding all types of electric motors (Alternating-Current & Direct-Current). We utilize state-of-the-art and innovative equipment at our facilities for AC & DC motor rewinding. Our electromechanical company arsenal includes qualified specialists, advanced technologies, vast experience, and affordable prices. You can order the repair of high-performance industrial electric motors with us at the most affordable rates. Over 30 years of experience and commitment to delivering quality service sets us apart from our competitors in the market. Because of our immense expertise and research, we can offer our customers a standard 12-month warranty on motor rewinds up to 11kv AC.

Production downtime is incredibly expensive. If a motor fails, it can lead to the shutdown of a production line. Electric motor rewinding usually takes less than 24 hours for small motors and less than three days for larger motors. We offer in-house and on-site emergency services as well. Our technicians will restore the efficiency of the equipment in the shortest possible time. With our quick turnaround and 24-hour service for motor rewinding, your equipment will be ready to use in no time. We have a wide range of winding and testing equipment to handle electric motors of all sizes, and we also offer generator and transformer rewinding services.

Electric motors are an integral part of various industries. AC/ DC motor is an essential component of machines from household items to industrial-level heavy equipment, right from water pumps, generators, chiller compressors, and refrigerators to conveyor belts and pumps in machine plants. At Ghaima Group, we serve many sectors, including marine, oil & gas, and power generation, that use all kinds of electromechanical equipment.

The cost of replacing the electric motor can be quite high. However, the DC& AC motor rewinding service can cut the cost in half. Our exceptional motor rewind service will have your machine up and running in no time and at the lowest possible cost. Motors can suffer many other damages that may include the destruction of the bearing, the grazing of the rotor on the stator, or the jamming of the shaft. Besides motor rewinding, we also offer an electric motor repair service at Ghaima Group.

Whether your industry uses a low-power or high-power electric motor, a synchronous or an AC induction motor, they all need rewinding after a while. The electric motor rewinding is carried out in accordance with the requirements of the regulations for each type of installation as specified by the manufacturer. For low-voltage machines, this period can be 5–7 years; for high-voltage models, the need arises much less often after 20–25 years. However, this is not always the case.

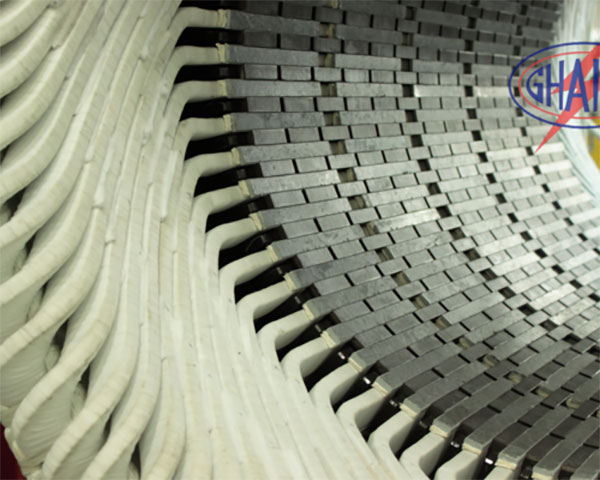

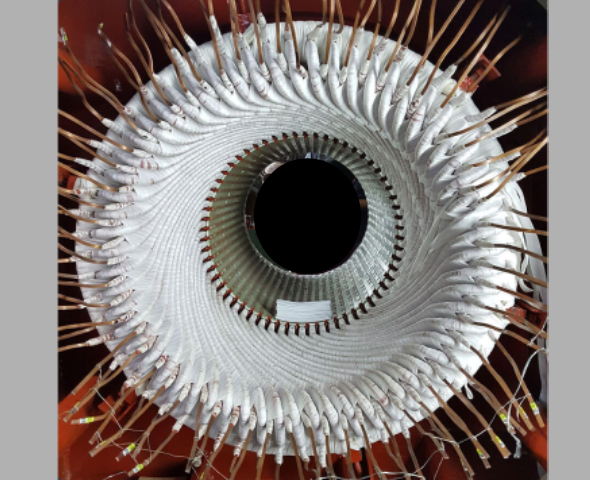

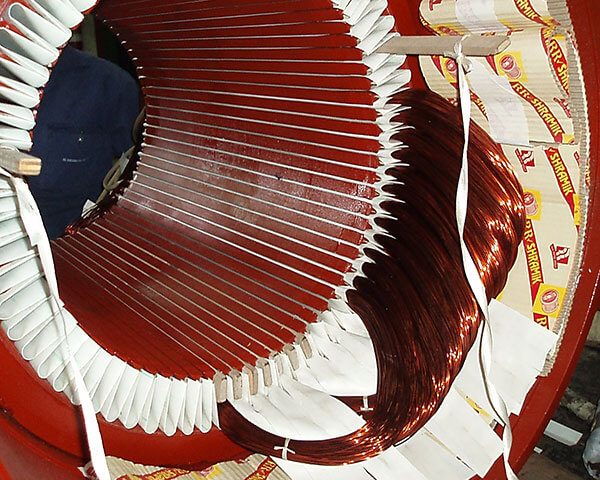

There are three phases in the rewinding of the electric motor: removing the damaged winding, new winding installation, and insulation. Our experts are trained in the planned upkeep of AC & DC motors, following all necessary steps incorporating mechanical engineering technology to regain the motor to its original configuration.

It is important to check the equipment to identify the issue thoroughly. Our specialists will conduct a comprehensive overhaul before starting with the electric motor rewinding steps.

After gathering vital data on the condition of the windings, the damaged motor windings are detached from the inside core of the machine in our machine shop.

What follows the removal of coils is the making of new wire coils. The key attributes of the process include layering, wire tension, and keeping track of the number of turns on the coil.

Once the coils are done, they are fabricated back into the stator slots and connected.

A few tests are implemented, such as a static, polarity index test, and resistance test, to guarantee the quality and mechanical integrity of the coils after the maintenance work. Afterward, the coils are insulated.