Precision maintenance in many industries depends on laser shaft alignment services. These services entail the precise alignment of rotating machinery shafts utilizing laser technology, assuring optimum performance and lowering the possibility of machinery malfunctions. Leading maritime engineering company Ghiama Group provides laser shaft alignment services that involve several important stages and factors to achieve perfect alignment. These services improve machinery reliability, energy efficiency, performance, and overall cost-effectiveness through a meticulous measurement, adjustment, and verification process.

Proper preparation is crucial for a successful alignment process. The process begins with collecting relevant data, such as machinery specifications, alignment tolerances, and thermal growth calculations. Technicians gather information about the machinery's coupling type, shaft sizes, rotational speeds, and any previous alignment issues.

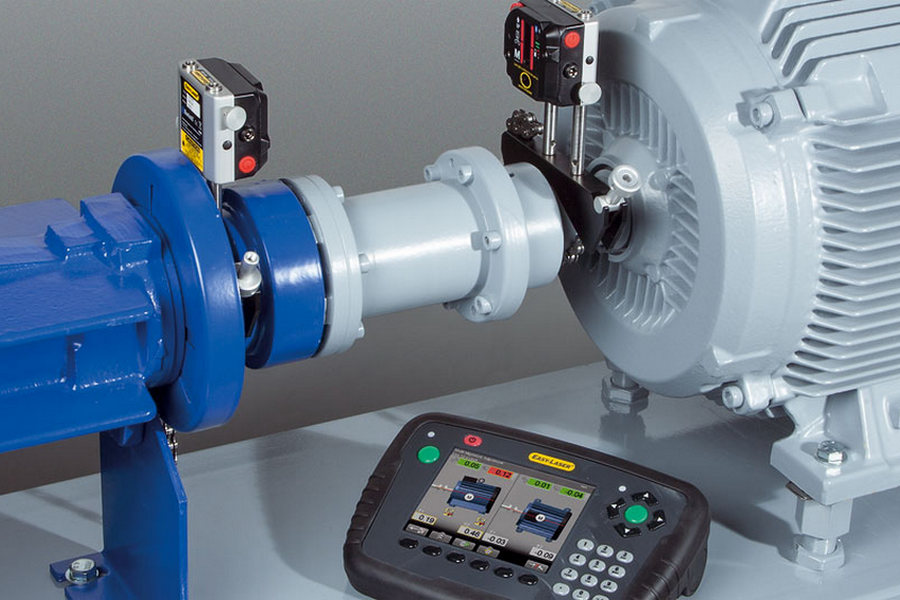

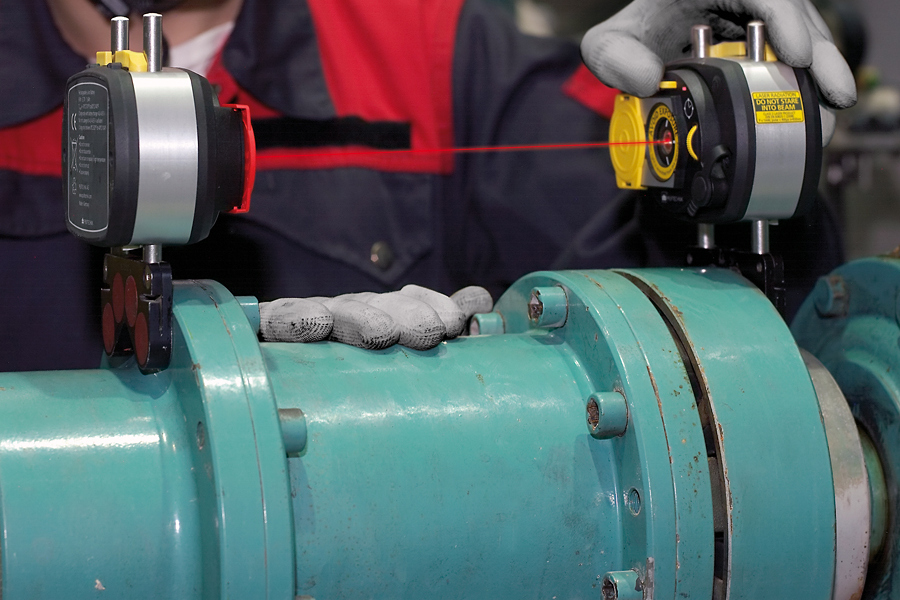

Laser alignment devices are used to measure the current misalignment between the shafts. These devices consist of a laser emitter and a detector that provide accurate readings of shaft positions. The initial measurements provide baseline data to determine the adjustments required for alignment.

Based on the initial measurements, technicians make precise adjustments to align the machinery shafts. This may involve modifying the shims, adjusting the mounting bolts, or realigning coupling elements. The goal is to minimize the misalignment between the shafts within specified tolerances.

Technicians check if the misalignment has been reduced to within acceptable limits. After adjustments, the laser alignment devices are used again to measure the alignment. This step helps ensure the accuracy of the alignment and confirms that the adjustments have been successfully implemented.

A comprehensive report is generated, documenting the alignment process, initial and final measurements, adjustments made, and any additional recommendations. This report serves as a reference for future maintenance and aids in tracking the machinery's alignment history.

These devices consist of a laser emitter and detector that measure the relative position of shafts. They provide real-time feedback on misalignment and assist in making precise adjustments.

Alignment software is used to interpret the measurement data and visually represent misalignment. It aids technicians in accurately assessing alignment conditions and guides them in making necessary adjustments.

Each machinery manufacturer sets specific alignment tolerances to ensure optimal performance and prevent premature wear or damage. Technicians follow these tolerances to achieve alignment within acceptable limits.

Machinery undergoes thermal expansion and contraction during operation, which affects alignment. Technicians account for this thermal growth and calculate compensation values to achieve accurate alignment at operating temperatures.

Proper alignment enhances machinery reliability by reducing rotating components' vibration, heat generation, and stress. This helps prevent premature failures and extends machinery’s lifespan.

Misaligned shafts result in increased energy consumption due to higher friction and inefficiencies. Laser shaft alignment reduces energy waste by aligning posts to minimize unnecessary power consumption.

Accurate alignment ensures optimal performance of rotating machinery, leading to improved productivity, reduced downtime, and higher-quality output.

Laser shaft alignment services contribute to cost savings by minimizing maintenance and repair expenses. Proper alignment reduces wear on components, lowers the risk of breakdowns, and eliminates the need for frequent replacements.

Well-aligned machinery reduces the risk of accidents, such as bearing failures or shaft breakages, which can cause harm to personnel and damage surrounding equipment.