Motor rewinding is a specialized service that helps keep electric motors running smoothly. Whether it's an AC or DC motor, if it stops working because of problems like burnt parts or old insulation, rewinding is needed to fix it and make it work again

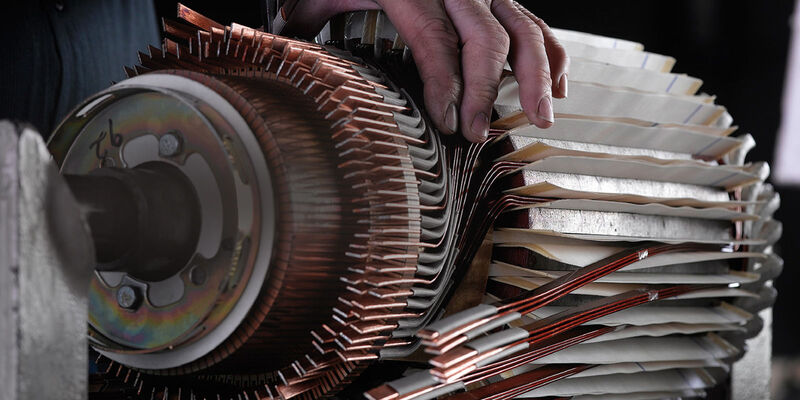

Rewinding a motor involves changing the old winding coils with new ones to repair it if it's broken. The process needs skilled people because they have to make sure the new coils are put in exactly the right way to make the motor work its best. Ghaima, a reliable mechanical and electrical company holds great expertise in offering the service through a dedicated and proficient team who maintain the original winding configuration and specifications for optimal motor performance.

This service focuses on direct current (DC) motors commonly used in various applications like small appliances, tools, and automotive systems. These motors feature different winding configurations, such as lap winding or wave winding, depending on their intended use and power requirements. Rewinding ensures that the motor operates efficiently and reliably.

It is crucial for alternating current (AC) motors found in industrial equipment, pumps, fans, and HVAC systems. These motors come in various types, including single-phase and three-phase, each requiring specific rewinding techniques. Proper rewinding restores the motor's functionality and extends its lifespan.

Assessment: Technicians inspect the motor to identify the extent of damage and determine if rewinding is the best solution.

Disassembly: The motor is disassembled carefully to access the stator and rotor, where the winding coils are located.

Removal: Damaged winding coils are removed from the motor's core, ensuring no further damage to other components.

Replacement: New winding coils, made of high-quality insulated wire, is meticulously installed according to the motor's original specifications.

Insulation: Proper insulation materials are applied between the winding layers to prevent short circuits and ensure electrical safety.

Testing: The rewound motor undergoes rigorous testing to verify its electrical performance, including insulation resistance and operating efficiency.

Reassembly: Once the motor passes all tests, it's reassembled, and additional maintenance tasks, such as bearing replacement or lubrication, may be performed.

Final Inspection: A final inspection ensures that the motor meets quality standards and is ready to be returned to service.

Cost-Effective: Rewinding is often more economical than purchasing a new motor.

Sustainable: Increases the life of motors that already exist, reducing waste.

Customization: Allows for customization of winding configurations to suit specific applications.

Faster Turnaround: In many cases, motor rewinding can be completed faster than sourcing a new motor.

In conclusion, electric motor rewinding is a vital service that helps restore the functionality of both AC and DC motors, ensuring continued operation and efficiency across various industries. With skilled technicians and attention to detail, motor rewinding offers a cost-effective solution to motor failures, minimizing downtime and maximizing productivity.